At Andymus Consulting we see process simulation is a critical tool in the design, analysis, and optimisation of industrial systems involving fluid flow, heat transfer, and chemical reactions.

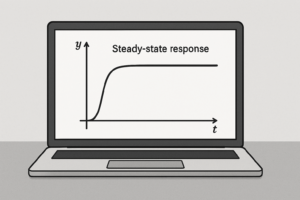

Two primary types of simulations are steady state and dynamic simulations, each serving distinct purposes in process engineering.

This page focuses on the application of steady state and dynamic process simulation techniques for the assessment of piping networks using leading simulation software tools such as Aspen HYSYS, Honeywell UniSim Design, SysCAD, MetSIM, Aspen Plus, and Modelica-based platforms.

Steady State Process Simulation

Steady state simulation assumes that process variables (pressure, temperature, flow rates, compositions) do not change with time. It is widely used for:

- Design and rating of piping networks

- Equipment sizing and specification

- Process optimisation under fixed operating conditions

- Troubleshooting and debottlenecking

Using HYSYS and UniSim for Steady State Simulation

- Both HYSYS and UniSim provide comprehensive steady state simulation environments with extensive thermodynamic models and unit operation libraries.

- They allow detailed modeling of piping networks including pressure drop calculations, flow distribution, and heat loss/gain.

- Users can simulate complex process flowsheets integrating piping with reactors, separators, heat exchangers, and compressors.

Modelica for Steady State

- Modelica, an object-oriented, equation-based language, supports steady state modeling through libraries such as ThermoFluid and Fluid.

- It enables flexible and customisable component modeling, suitable for research and advanced engineering applications.

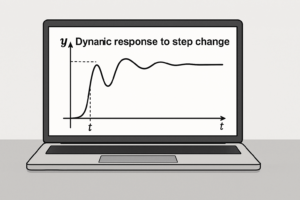

Dynamic Process Simulation

Dynamic simulation captures the time-dependent behavior of process systems, essential for:

- Transient analysis and control system design

- Safety and relief system evaluation

- Startup, shutdown, and emergency scenario modeling

- Process control strategy development

Dynamic Simulation in HYSYS and UniSim

- Both platforms offer dynamic simulation modules that extend steady state models with time-dependent equations.

- They support rigorous modeling of transient phenomena such as pressure surges, fluid hammer, and control valve responses.

Modelica for Dynamic Simulation

- Modelica excels in dynamic simulation with its acausal modeling approach and powerful solvers.

- Libraries like Modelica.Fluid provide detailed hydraulic and thermal dynamic models for piping networks.

- It is widely used for simulating complex transient events and control interactions.

Network of Piping Assessment

Assessment of piping networks involves evaluating pressure drops, flow distribution, temperature profiles, and transient responses to ensure safe and efficient operation.

Key Considerations

- Accurate thermodynamic and fluid property models (in particular for compressible gas)

- Detailed representation of pipe geometry, fittings, and insulation

- Integration with upstream and downstream process units

- Consideration of multiphase flow where applicable

Software Comparison

| Feature | Aspen HYSYS | Honeywell UniSim | Modelica Frameworks |

|---|---|---|---|

| Steady State Simulation | Comprehensive | Comprehensive | Flexible, customisable |

| Dynamic Simulation | Available | Available | Advanced, acausal |

| Thermodynamics | Extensive library | Extensive library | Depends on libraries |

| User Interface | GUI-based | GUI-based | Textual/Graphical tools |

| Customisation | Limited scripting | Limited scripting | High (open source) |

Conclusion

Steady state and dynamic process simulations are indispensable for piping network assessment. The choice of tool depends on project requirements, complexity, and user expertise. HYSYS and UniSim offer robust commercial solutions with user-friendly interfaces, while Modelica provides a powerful open modeling environment for advanced and customised simulations.